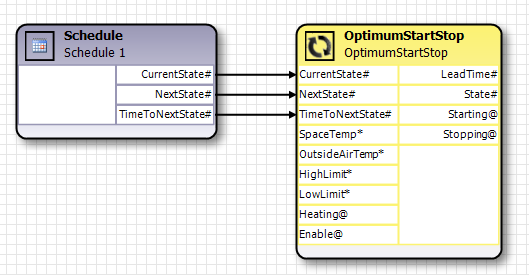

Performs start time and stop time optimization using a Schedule programming block, and are usually linked in a program:

Most facilities have predicable occupancy patterns to which the mechanical equipment is scheduled to run during the occupied times of day. Based on this schedule, there are two types of optimization: Start Time Optimization and Stop Time Optimization.

Start Time Optimization -- Typically, HVAC equipment should be started some time prior to the building becoming occupied for the occupied spaces to be comfortable when occupants arrive. As an alternative to starting the equipment a fixed time prior to occupancy, the OptimumStartStop block can be used to calculate the optimum time prior to occupancy that the equipment should be started to attain the comfort levels required when occupants arrive.

The OptimumStartStop block achieves its goal of preparing the space to meet the target setpoint by initiating the start of the equipment at a calculated lead time prior to scheduled occupancy. The equipment can be configured to aggressively heat or cool the space during the lead time.

Lead time is the number of minutes prior to the scheduled occupied time that the equipment serving the occupied space should be started to ensure the space is at target setpoint when it is scheduled to be occupied. If for example the space is scheduled to be occupied at 8:00am and the Optimum Start functional block calculates a lead time of 13 minutes is needed to ready the space then the equipment will be started at 8:00am minus 13 minutes or 7:47am.

The OptimumStartStop calculates a lead time only when all of the appropriate conditions are met, which are:

•schedule is in the unoccupied or standby state, and

•the next scheduled state is occupied, and

•The space temperature is outside the comfort limits defined by HighLimit and LowLimit

•the time to next state is less than the configured maximum lead time

The Optimum Start functional block uses statistical information to automatically calculate the lead time required for certain conditions as indicated by the OutsideAirTemp. This self-tuning feature allows the Optimum Start functional block to learn (optimize) how long the lead time should be for certain conditions. The information is stored as the gain. Gain is the rate in degrees per hour at which the equipment can raise or lower the monitored variable toward the target setpoint, based on past historical performance for a given range of outside air temperature. Separate gains are kept for pre-cool and for morning warmup; corresponding to the ranges of OutsideAirTemp. Different gains for heating and cooling are important because equipment with different characteristics are often used for cooling and heating.

Gain is calculated during the pre-cool or morning warmup sequence, when the temperature has reached the targets defined by the temperature limits defined by HighLimit and LowLimit. If the initial temperature was greater than HighLimit, then the temperature must reach a target temperature of HighLimit – Deadband. If the initial temperature was less than LowLimit, then the temperature must reach a target temperature of LowLimit + Deadband. The gain calculation is not performed if the temperature does not reach the target temperature.

Stop Time Optimization – Typically, the mechanical equipment would be stopped at the time that the building becomes unoccupied. As an alternative to stopping the equipment at the end of the occupied period, the OptimumStartStop block can be used to calculate the optimum time prior to unoccupied when the equipment can be stopped that allows the building to “drift” and stay within the comfort range.

The OptimumStartStop block achieves it goal turning off the equipment at the earliest possible time by initiating the stop of the equipment at a calculated lead time prior to scheduled unoccupancy.

The OptimumStartStop block uses statistical information to automatically calculate the shut down time required for certain conditions as indicated by the OutsideAirTemp. This self‑tuning feature allows the OptimumStartStop block to learn (optimize) how long the time should be for certain conditions. The information is stored as the “drift”. Drift is the rate in degrees per hour at which the space temperature will drift from current (comfortable) space temperature. The block will keep separate drift values for the current mode (heating or cooling - supplied by the Heating slot) and corresponding to the ranges of OutsideAirTemp.

The OptimumStartStop calculates a lead time only when all of the appropriate conditions are met, which are:

•schedule is in the occupied state

•the next scheduled state is unoccupied, or standby

•The space temperature is within the comfort limits defined by HighLimit and LowLimit

•the time to next state is less than the configured maximum lead time

Drift is calculated when the occupancy state transitions to unoccupied, as long as the temperature has been maintained within the targets defined by the temperature limits defined by HighLimit and LowLimit. If the system was heating (as defined by the Heating slot), then the system must drift below a target temperature of LowLimit - Deadband. If the system was not heating, then the temperature must not drift beyond a target of HighLimit + Deadband.

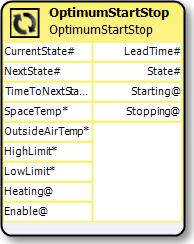

Inputs |

|

|||||

|

Slots |

Type |

Default |

Description |

||

|

CurrentState |

Integer |

|

The current SNVT_occupancy state in the schedule: 0 = OC_OCCUPIED – the area is occupied 1 = OC_UNOCCUPIED – the area is unoccupied 2 = OC_BYPASS - the area is temporarily occuped 3 = OC_STANDBY – the area is temporarily unoccupied |

||

|

NextState |

Integer |

|

The next SNVT_occupancy state in the schedule. |

||

|

TimeToNextState |

Integer |

|

The time, in minutes, until the next state is achieved. |

||

|

SpaceTemp |

Numeric |

|

The space temperature of the occupied area. |

||

|

OutsideAirTemp |

Numeric |

|

The outside air temperature. |

||

|

HighLimit |

Numeric |

|

The highest comfortable temperature for the occupied space. |

||

|

LowLimit |

Numeric |

|

The lowest comfortable temperature for the occupied space. |

||

|

Heating |

Digital |

|

Used during stop time optimization so the block knows if the system was heating or cooling. |

||

|

Enabled |

Digital |

True |

Enables or disables the block. |

||

Outputs |

|||

|

Slots |

Type |

Description |

|

LeadTime |

Integer |

The calculated lead time, in minutes. |

|

State |

Integer |

The current state of the block: ▪STATE_NONE = 0 ▪STATE_START_CALCULATION = 1 ▪STATE_START_INPROGRESS = 2 ▪STATE_START_COMPLETE = 3 ▪STATE_STOP_CALCULATION = 4 ▪STATE_STOP_INPROGRESS = 5 ▪STATE_STOP_COMPLETE = 6 |

|

Starting |

Digital |

When performing start time optimization, this slot is set to True when the LeadTime >= TimeToNextState (i.e. the equipment should be heating or cooling). |

|

Stopping |

Digital |

When performing stop time optimization, this slot is set to True when the LeadTime >= TimeToNextState (i.e. the equipment should be turned off). |

Properties |

||

|

Slots |

Description |

|

Deadband |

Deadband is combined with the ‘HighLimit’ and ‘LowLimit ‘ to determine the limits of the acceptable temperatures. |

|

MaxLeadStartTime |

Specifies the maximum number of minutes prior to scheduled occupied state that the optimum start cycle can begin. |

|

MinLeadStartTime |

Specifies the minimum number of minutes prior to scheduled occupied state that the optimum start cycle can begin. |

|

MaxLeadStopTime |

Specifies the maximum number of minutes prior to scheduled unoccupied state that the optimum stop cycle can begin. |

|

MinLeadStopTime |

Specifies the minimum number of minutes prior to scheduled unoccupied state that the optimum stop cycle can begin. |

|

Units |

Can be set to one of the following values: ▪US: values on the ‘SpaceTemp’ and ‘OutsideAirTemp’ input slots are expected to be in Fahrenheit. ▪SI: values on the ‘SpaceTemp’ and ‘OutsideAirTemp’ input slots are expected to be in Celsius. |